بررسی مزایای توری صفحه پلی اورتان در کاربردهای صنعتی

درک نقش مش فرکانس بالا در فناوری مدرن

مش های فرکانس بالا، به ویژه آنهایی که از پلی اورتان ساخته شده اند و در پانل های مش گنجانده شده اند، نقشی اساسی در فناوری مدرن ایفا می کنند. این مش ها اجزای جدایی ناپذیر در صنایع مختلف از جمله معدن، ساخت و ساز و مخابرات و غیره هستند. آنها برای مقاومت در برابر ارتعاشات با فرکانس بالا طراحی شده اند و برای استفاده در تجهیزاتی که تحت شرایط شدید کار می کنند ایده آل هستند.

high frequency mesh, particularly those made from polyurethane and incorporated into mesh panels, plays a pivotal role in modern technology. These meshes are integral components in a variety of industries, including mining, construction, and telecommunications, among others. They are designed to withstand high-frequency vibrations, making them ideal for use in equipment that operates under intense conditions.

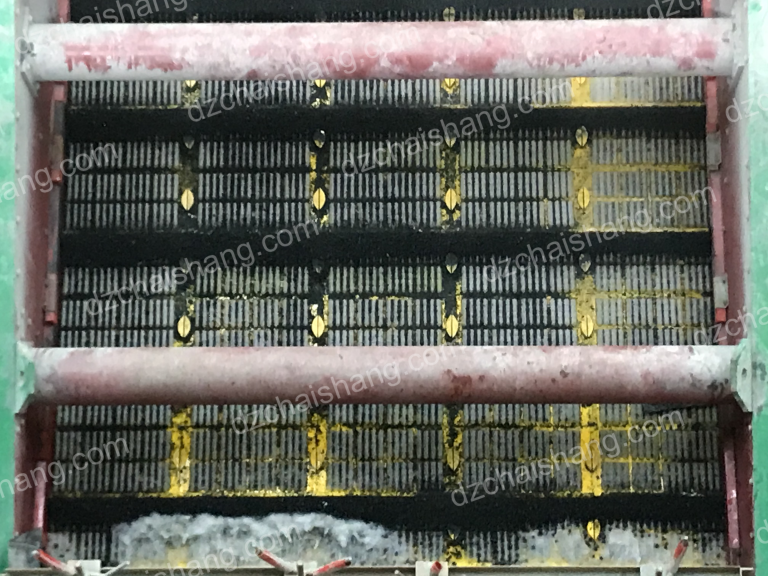

polyurethane screen mesh, a type of high frequency mesh, is renowned for its durability and resilience. Polyurethane is a versatile material that combines the best properties of plastic and rubber. It is resistant to abrasion, corrosion, and impact, making it an excellent choice for high-frequency applications. The elasticity of polyurethane allows the mesh to absorb impact and resist damage, while its hardness ensures that it can withstand high levels of wear and tear. This unique combination of properties makes polyurethane screen mesh an indispensable tool in industries that require robust and reliable equipment.

Mesh panels made from high frequency mesh are used in a variety of applications. In the mining industry, for instance, they are used in screening equipment to separate different sizes of minerals and ores. The high frequency vibrations help to break down larger pieces of material, while the mesh panels ensure that only particles of the desired size pass through. This not only improves the efficiency of the mining process but also enhances the quality of the extracted materials.

In the construction industry, high frequency mesh is used in concrete reinforcement. The mesh panels provide additional strength and stability to the concrete, preventing cracks and other forms of damage. The high frequency vibrations help to ensure that the concrete is evenly distributed, resulting in a stronger and more durable structure.

In the telecommunications industry, high frequency mesh is used in antennas and other communication devices. The mesh acts as a filter, allowing certain frequencies to pass through while blocking others. This helps to improve the clarity and reliability of the signal, ensuring that the communication is clear and uninterrupted.

Despite their widespread use, high frequency mesh panels are not without their challenges. The high frequency vibrations can cause the mesh to wear out over time, reducing its effectiveness. However, advances in technology have led to the development of more durable materials and designs. For instance, polyurethane screen mesh is now reinforced with steel wires or other strong materials to increase its lifespan.

In addition, the manufacturing process of high frequency mesh has also evolved. Modern manufacturing techniques allow for the production of mesh with precise dimensions and consistent quality. This ensures that the mesh performs reliably, regardless of the conditions under which it is used.