How China Vibrator PU tension screen Dewatering Can Improve Ore Processing Efficiency

The efficient processing of ore is essential for the success of any mining operation. In recent years, the use of vibrator PU tension screen dewatering technology has become increasingly popular in the ore processing industry due to its ability to improve efficiency and reduce costs. This technology is particularly beneficial for China’s ore processing industry, as it can help to reduce the amount of water used in the process, as well as improve the quality of the ore.

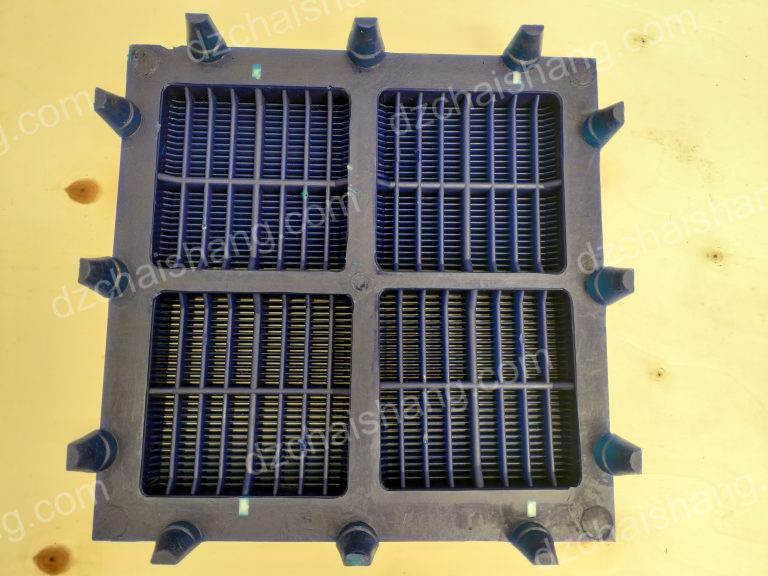

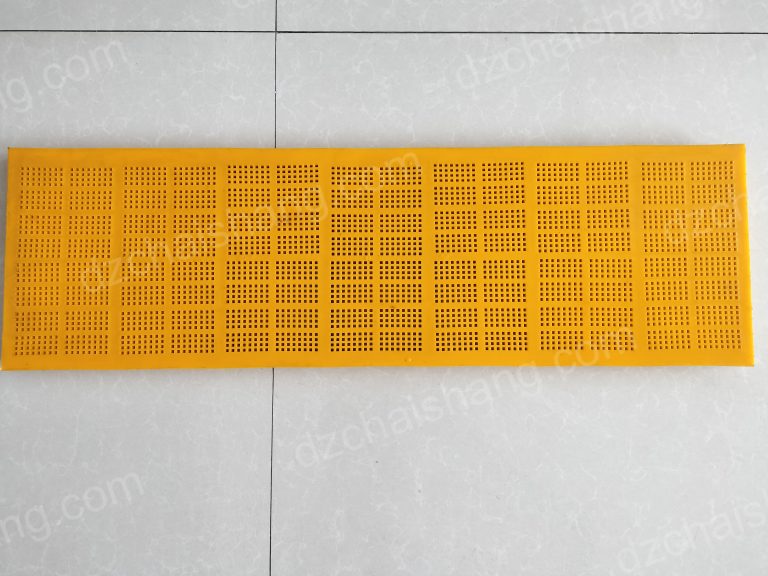

The vibrator PU tension screen dewatering technology works by using a vibrating screen to separate the ore from the water. This process is more efficient than traditional methods, as it requires less water and produces a higher quality ore. The vibrating screen also helps to reduce the amount of time needed to process the ore, as it can quickly separate the ore from the water. Additionally, the vibrating screen can be adjusted to different levels of intensity, allowing for more precise control over the ore processing process.

The vibrator PU tension screen dewatering technology also helps to reduce the amount of energy used in the ore processing process. This is because the vibrating screen requires less energy to operate than traditional methods, which can help to reduce the overall cost of the process. Additionally, the vibrating screen can be adjusted to different levels of intensity, allowing for more precise control over the ore processing process.

Overall, the vibrator PU tension screen dewatering technology is an effective way to improve ore processing efficiency in China. This technology can help to reduce the amount of water used in the process, as well as improve the quality of the ore. Additionally, it can help to reduce the amount of energy used in the ore processing process, which can help to reduce the overall cost of the process. As such, this technology is an ideal solution for China’s ore processing industry.

Exploring the Benefits of Using Shaker PU Tension Media Ore for Ore Processing

The use of Shaker PU Tension Media Ore for ore processing has become increasingly popular in recent years due to its numerous benefits. This type of ore processing offers a number of advantages over traditional methods, including improved efficiency, reduced costs, and increased safety. In this article, we will explore the benefits of using Shaker PU Tension Media Ore for ore processing and compare it to traditional methods.

One of the primary benefits of using Shaker PU Tension Media Ore for ore processing is its improved efficiency. This type of ore processing utilizes a vibrating screen to separate the ore particles from the waste material. This process is much faster than traditional methods, which often require manual sorting and separation. Additionally, the vibrating screen is able to separate particles of different sizes, allowing for more precise sorting and separation. This improved efficiency can lead to increased productivity and reduced costs.

Another benefit of using Shaker PU Tension Media Ore for ore processing is its increased safety. This type of ore processing does not require the use of hazardous chemicals or other potentially dangerous materials. Additionally, the vibrating screen is designed to reduce the risk of dust and other airborne particles, which can be hazardous to workers. This improved safety can lead to fewer accidents and improved worker morale.

Finally, using Shaker PU Tension Media Ore for ore processing can also lead to reduced costs. This type of ore processing requires less energy and fewer resources than traditional methods. Additionally, the vibrating screen is designed to reduce the amount of waste material produced, which can lead to lower disposal costs.

In conclusion, the use of Shaker PU Tension Media Ore for ore processing offers a number of advantages over traditional methods. This type of ore processing is more efficient, safer, and more cost-effective than traditional methods. As such, it is an ideal choice for ore processing operations.