Erkundung der verschiedenen Materialien, die in Vibrationssiebgeweben verwendet werden

Vibrationssiebgewebe ist ein unverzichtbarer Bestandteil verschiedener Branchen, darunter Bergbau, Steinbrüche und Mineralverarbeitung. Es spielt eine entscheidende Rolle beim Sieben, Sortieren und Trennen von Materialien nach ihrer Größe. Die Wirksamkeit eines Rüttelsiebgewebes hängt maßgeblich von dessen Material und Typ ab. Daher ist das Verständnis der unterschiedlichen Materialien, die in Rüttelsiebgeweben verwendet werden, und der verschiedenen verfügbaren Typen von entscheidender Bedeutung für die Auswahl des am besten geeigneten Materials für bestimmte Anwendungen.

Das Material eines Rüttelsiebgewebes ist ein entscheidender Faktor, der seine Haltbarkeit, Effizienz und Gesamtleistung bestimmt Leistung. Zu den am häufigsten verwendeten Materialien gehören Stahl, Edelstahl und Polyurethan. Stahl ist aufgrund seiner hohen Festigkeit und Verschleißfestigkeit eine beliebte Wahl. Es ist ideal für Hochleistungsanwendungen und hält rauen Umgebungsbedingungen stand. Allerdings ist es anfällig für Rost und Korrosion, was seine Langlebigkeit beeinträchtigen kann.

Andererseits bietet Edelstahl eine langlebigere und korrosionsbeständigere Alternative. Es ist rostbeständig und eignet sich daher für Anwendungen in nassen oder feuchten Umgebungen. Edelstahl-Vibrationssiebgewebe bieten außerdem eine hervorragende Hitzebeständigkeit und eignen sich daher ideal für Branchen wie die Lebensmittelverarbeitung und die chemische Fertigung.

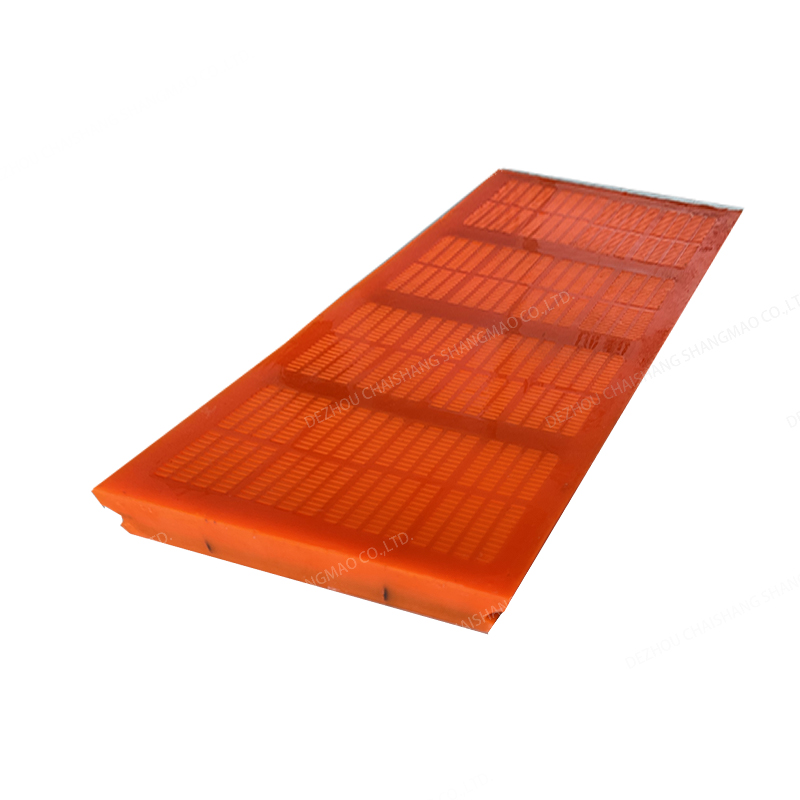

Polyurethan ist ein weiteres Material, das aufgrund seiner einzigartigen Eigenschaften immer beliebter wird. Es ist hochflexibel und bietet eine hervorragende Abriebfestigkeit, wodurch es sich ideal zum Sieben abrasiver Materialien eignet. Polyurethan bietet außerdem eine hervorragende Geräuschreduzierung und ist daher die bevorzugte Wahl für Anwendungen, bei denen die Geräuschreduzierung Priorität hat.

Neben dem Material spielt auch die Art des Vibrationssiebgewebes eine wichtige Rolle für seine Leistung. Zu den gebräuchlichsten Typen gehören Drahtgeflechte, Lochbleche und Keildrahtsiebe. Gewebtes Drahtgeflecht ist der traditionellste Typ und bekannt für seine Haltbarkeit und hohe Siebeffizienz. Es ist in verschiedenen Webmustern erhältlich, darunter Leinwandbindung, Köperbindung und holländische Bindung, die jeweils unterschiedliche Grade an Filtrationspräzision bieten.

Lochplatten hingegen sind für ihre hohe Festigkeit und Haltbarkeit bekannt. Sie sind ideal für Hochleistungsanwendungen und können große Materialmengen verarbeiten. Die Größe und das Muster der Löcher können individuell angepasst werden, um spezifische Siebanforderungen zu erfüllen.

Keildrahtsiebe sind eine weitere Art von Vibrationssiebgeweben, die eine hohe Präzision und Effizienz bieten. Sie bestehen aus V-förmigen Drähten, die auf Stützstangen geschweißt sind, wodurch eine starre Struktur entsteht, die hohem Druck standhält. Das einzigartige Design ermöglicht hervorragende Entwässerungseigenschaften und eignet sich daher ideal für Anwendungen in der Abwasseraufbereitungsindustrie.

Schließlich ist das vibrierende lineare Siebgewebe eine Art vibrierendes Siebgewebe, das für die Siebung mit linearer Bewegung entwickelt wurde. Es zeichnet sich durch seine geradlinige Flugbahn aus, die eine effiziente Siebung von Materialien ermöglicht. Diese Art von Gewebe wird häufig in Branchen wie Bergbau und Steinbrüchen verwendet, in denen ein hoher Durchsatz erforderlich ist.

Zusammenfassend lässt sich sagen, dass das Material und die Art des Vibrationssiebgewebes seine Leistung und Eignung für verschiedene Anwendungen erheblich beeinflussen. Ob Stahl, Edelstahl oder Polyurethan, jedes Material bietet einzigartige Vorteile. Ebenso dient die Art des Gewebes, sei es Drahtgewebe, Lochbleche, Keildrahtsiebe oder vibrierende lineare Siebgewebe, jeweils einem bestimmten Zweck. Daher ist das Verständnis dieser Aspekte entscheidend für eine fundierte Entscheidung bei der Auswahl eines Rüttelsiebgewebes.