Exploring the Advantages and Applications of polyurethane screen panels

Exploring the Advantages and Applications of Polyurethane screen panels In the world of material separation and screening, efficiency and durability are paramount. Polyurethane screen panels, commonly referred to as pu screen panels, have emerged as a superior alternative to traditional screening media such as wire mesh and steel. These innovative panels are crafted from high-quality urethane materials, offering a unique combination of resilience, flexibility, and longevity that is transforming the screening industry. One of the most significant advantages of polyurethane screening is its exceptional wear resistance. Unlike metal screens that can corrode or wear down quickly, PU screen panels are designed to withstand harsh abrasive materials, reducing the frequency of replacements and maintenance. This durability is not only cost-effective but also ensures consistent performance over time, which is crucial for industries that rely on continuous operation. Moreover, the elasticity of urethane screen panels plays a pivotal role in their effectiveness. The flexibility of the material allows the panels to absorb impact and reduce the likelihood of blinding and pegging, common issues that can hinder the screening process. This elasticity also contributes to better noise reduction compared to metal screens, creating a more pleasant work environment and reducing noise pollution.

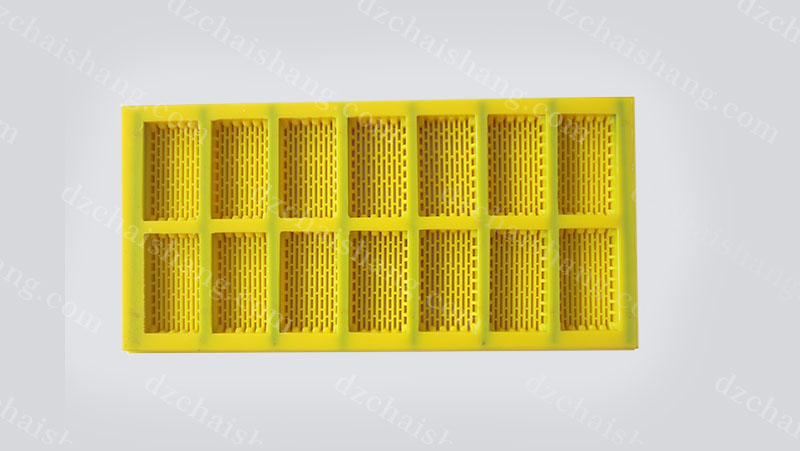

Another noteworthy feature of PU screen panels is their versatility. They can be manufactured in a wide range of hardness levels, which means they can be tailored to suit various applications, from fine to heavy-duty screening. Additionally, polyurethane can be molded into different shapes and sizes, allowing for custom designs that fit specific machinery and meet unique operational requirements.

Moreover, the elasticity of urethane screen panels plays a pivotal role in their effectiveness. The flexibility of the material allows the panels to absorb impact and reduce the likelihood of blinding and pegging, common issues that can hinder the screening process. This elasticity also contributes to better noise reduction compared to metal screens, creating a more pleasant work environment and reducing noise pollution.

Another noteworthy feature of PU screen panels is their versatility. They can be manufactured in a wide range of hardness levels, which means they can be tailored to suit various applications, from fine to heavy-duty screening. Additionally, polyurethane can be molded into different shapes and sizes, allowing for custom designs that fit specific machinery and meet unique operational requirements.The applications of urethane screen panels are diverse and span across multiple industries. In mining and quarrying, they are used to separate minerals and aggregates based on size, ensuring that only material of the desired dimensions passes through. The oil and gas industry benefits from the fine screening capabilities of PU panels, which are essential in the separation of drilling fluids and cuttings. Recycling operations also utilize these panels to sort materials such as glass, metal, and plastic, contributing to more efficient and sustainable practices. Furthermore, the agricultural sector employs polyurethane screening in the processing of various crops, where gentle handling is necessary to preserve the integrity of seeds and grains. Even in the food industry, where hygiene standards are stringent, the non-toxic and easy-to-clean nature of PU screen panels makes them an ideal choice for food processing applications. In terms of installation and handling, polyurethane screen panels are lightweight compared to their metal counterparts, making them easier and safer to install. This ease of handling reduces downtime during screen changes and minimizes the risk of injury to personnel. In conclusion, the adoption of polyurethane screen panels is a testament to the material’s superior properties and the industry’s commitment to innovation. With their remarkable wear resistance, flexibility, and customizability, PU screen panels offer a cost-effective and efficient solution for a wide array of screening applications. As industries continue to seek out ways to optimize their operations and reduce environmental impact, it is clear that urethane screen panels will play an increasingly vital role in the material separation processes of the future.