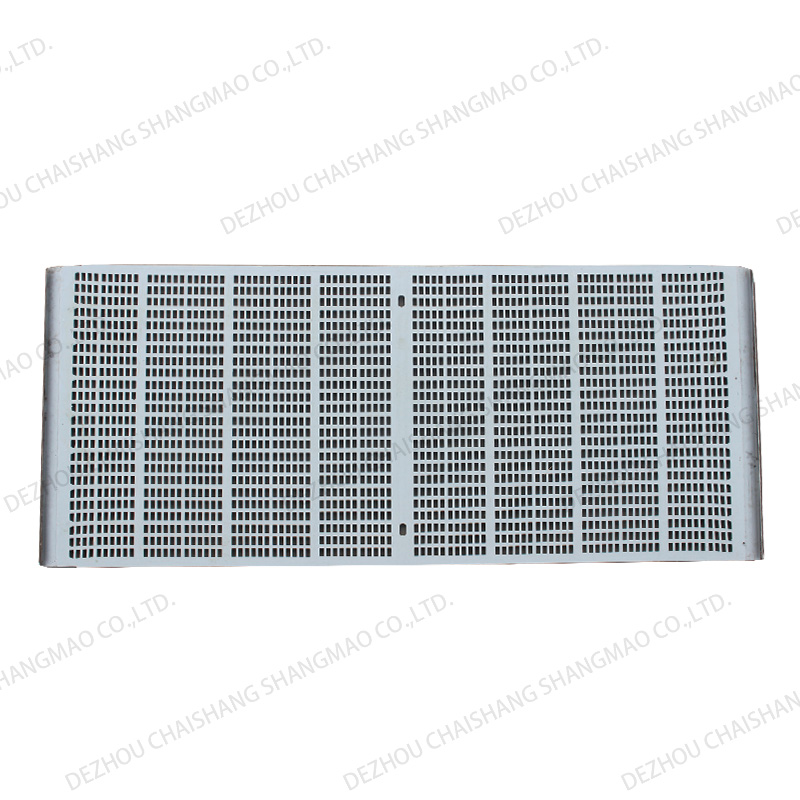

PU Screen panel for Sandvik screening machine

Material: Polyurethane

Hardness: 80-95 Shore A

Customization: Available

Standard service life: 6~12 months

Delivery: 15-45 days depending on the quantity

- Satisfaction Guaranteed

- Accurate dimensions

- Guaranteed installation

- On-time delivery

Description

pu wire mesh also known as “wire rope core polyurethane mesh, PU Coated Wire Mesh, Steel Core screen mesh, PU Mesh, is widely used in screening machines in metallurgy, mining, coal, building materials, water conservancy, road construction, and other industries. It is a board replacement product for steel plate punching screens, steel wire braided screens, stainless steel screens, and rubber screens.

Features

It has the advantages of a lightweight, high screening efficiency, non-blocking holes, anti-friction, impact resistance, tear resistance, long life (2-3 times that of stainless steel sieve plate), low noise, and convenient installation, and high comprehensive benefits.

PU wire mesh has a unique structure, suitable elasticity, and plastic force, which can reduce jamming, and reduce the blocking due to the second harmonic high-frequency vibration of the screen bar. High practical opening rate and high screening efficiency. Polyurethane support nets are provided with elastic tensioning hooks on both sides. The overall weight is light, the flexibility is good, the transportation and storage are easy, and the installation and disassembly are convenient.PU wire mesh and screen can effectively absorb impact, reduce noise and improve the working environment. At present, the range of use of polyurethane support nets has been further developed. The screen holes can be made into squares or rectangles. The size of each side of the holes can be adjusted by 2 to 45 mm. Customized size and aperture size is available according to your special needs.