Benefits And Applications Of Double Deck modular polyurethane screen panels In mining Operations

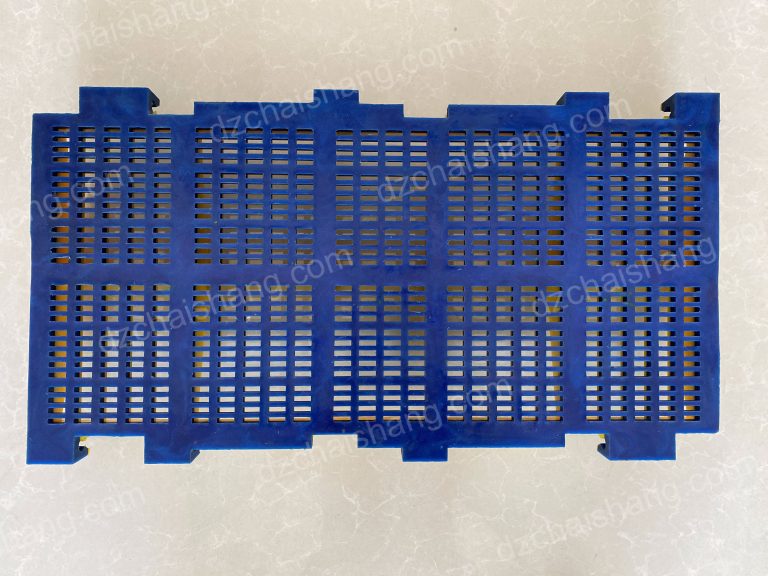

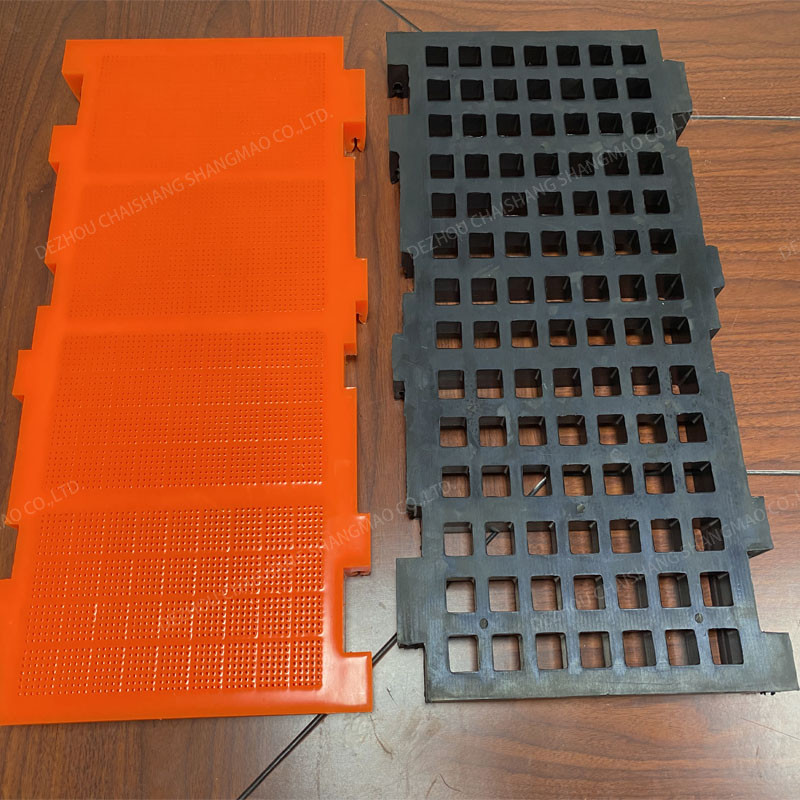

Double deck modular polyurethane screen panels, commonly referred to as polyurethane panel mesh, represent a significant advancement in mining technology. These innovative screening solutions offer a multitude of benefits that enhance both the efficiency and cost-effectiveness of mining operations. Developed to address the rigorous demands of the mining industry, these panels are crafted from polyurethane, which is known for its exceptional durability and resistance to wear and tear. One of the primary advantages of polyurethane screen panels is their longevity. Unlike traditional wire mesh screens, polyurethane screens are not prone to rusting or corrosion. This characteristic is particularly valuable in mining environments, where screens are frequently exposed to wet and abrasive materials. The resilience of polyurethane extends the lifespan of the screens, thereby reducing the frequency of replacements and minimizing downtime. This durability also makes them an economical choice over the long term, as the initial investment is offset by the decreased maintenance costs and fewer replacements. Moreover, double deck modular polyurethane screen panels are highly effective in separating and processing ores. These panels are designed with precision to ensure that they can handle varying feed sizes and types of materials. The configuration of the double deck design allows for better segregation and processing of materials. The top deck can be used for the initial screening of larger particles, while the lower deck can be dedicated to the finer screening. This tiered approach not only improves the accuracy of the screening process but also enhances the overall output by facilitating a more thorough separation of materials. The flexibility in customization is another significant benefit of these panels. They can be manufactured to fit a variety of screen decks and machine types. This adaptability ensures that they can be integrated into nearly any screening setup without the need for extensive modifications. The modular nature of these panels also simplifies the process of installation and replacement, which can be particularly beneficial in reducing operational interruptions during routine maintenance. In addition to their structural advantages, polyurethane screen panels contribute to environmental sustainability. Their increased efficiency helps in reducing the waste generated during the screening process. By more effectively separating materials, these panels ensure that less unprocessed ore is discarded. This not only conserves valuable resources but also decreases the environmental impact associated with the mining operations. The applications of double deck modular polyurethane screen panels extend across various types of mining operations, from coal and iron ore to gold and copper mining. In each of these applications, the panels provide enhanced screening efficiency that is crucial for the optimization of the mining process. Their impact is particularly notable in operations where fine particle separation is essential. In such scenarios, the precision and efficiency of Polyurethane Panels play a pivotal role in ensuring the quality of the final product. In conclusion, double deck modular polyurethane screen panels are a vital component in modern mining operations. Their robust construction and innovative design not only improve the efficiency and effectiveness of the screening processes but also contribute to significant cost savings and environmental benefits. As the mining industry continues to evolve, these panels are likely to become even more integral to mining operations, driving further advancements in mining technology and sustainability.Comparison Of Polyurethane Panel Mesh With Traditional Screening Materials In Construction And Agriculture

Double deck modular polyurethane screen panels, commonly referred to as polyurethane panel mesh, have increasingly become a preferred choice in various sectors, notably in construction and agriculture. This preference arises from their unique characteristics when compared to traditional screening materials such as wire mesh or steel. The comparison hinges on several key factors including durability, efficiency, environmental impact, and cost-effectiveness, which are pivotal in determining their applicability across different industries. Durability is one of the foremost benefits of polyurethane panel mesh. Unlike traditional materials like steel, which can corrode, or wire mesh that often suffers from wear due to abrasion, polyurethane is highly resistant to both. This synthetic material can withstand harsh environmental conditions, including exposure to oils, water, and ultraviolet radiation, making it more suitable for outdoor and industrial applications where longevity is critical. This durability not only extends the life of the screens but also reduces the frequency of replacements, providing long-term cost savings and less frequent interruptions to operations. In terms of efficiency, polyurethane panel mesh excels due to its superior flexibility and vibration absorption qualities. These properties allow it to maintain more contact with the material being screened, thereby increasing the accuracy of the screening process. For construction and agriculture, where material grading and size differentiation are crucial, the ability of polyurethane panels to prevent blinding and maintain consistent pore size under stress ensures better material separation and reduces wastage.From an environmental standpoint, the long service life and reduced need for replacement of polyurethane screens translate into less waste generated over time. Moreover, the manufacturing process of polyurethane typically involves lower energy consumption compared to metals, which require high-energy inputs during mining and processing. Consequently, the overall environmental footprint of polyurethane panels is considerably lower than that of traditional materials, aligning with the growing emphasis on sustainability in industry practices. Cost-effectiveness, while initially not apparent due to the higher upfront cost of polyurethane panels compared to wire mesh or steel, becomes evident when considering the lifecycle costs. The durability and efficiency of polyurethane reduce the total cost of ownership by minimizing downtime, maintenance, and replacement expenses. In construction projects where timelines and budgets are tight, and in agricultural operations where cost control is essential, these factors make polyurethane an economically viable option over the long term. Furthermore, the adaptability of polyurethane to various architectural and functional designs in construction enhances its utility. It can be molded into different shapes and sizes, equipped with varying degrees of hardness and tensile strength to match specific operational requirements. This versatility is particularly beneficial in construction projects that involve unique architectural elements or require custom solutions for material separation.

In conclusion, when comparing polyurethane panel mesh with traditional screening materials like wire mesh and steel in the fields of construction and agriculture, it is evident that polyurethane offers significant advantages. Its superior durability, efficiency in screening, reduced environmental impact, and overall cost-effectiveness make it a compelling choice for modern industrial applications. As industries continue to seek sustainable and efficient materials, the role of polyurethane panel mesh is likely to expand, reinforcing its importance in future development projects.