Pros and Cons of Direct Sale PU Linear Vibrating Deck Dewatering

Direct sale PU linear vibrating deck dewatering is a popular method used in various industries to separate solid particles from liquids. This process involves the use of a vibrating deck that helps to dewater the material by removing excess moisture. While this method has its advantages, there are also some drawbacks to consider.

One of the main advantages of direct sale PU linear vibrating deck dewatering is its efficiency. The vibrating deck helps to quickly and effectively separate the solid particles from the liquid, resulting in a drier end product. This can help to increase productivity and reduce processing time, making it a cost-effective solution for many industries.

Another benefit of direct sale PU linear vibrating deck dewatering is its versatility. This method can be used to dewater a wide range of materials, including coal, sand, and minerals. It can also be customized to meet the specific needs of different industries, making it a versatile option for many applications.

In addition to its efficiency and versatility, direct sale PU linear vibrating deck dewatering is also relatively easy to operate. The equipment is designed to be user-friendly, with simple controls that make it easy to adjust the settings and monitor the dewatering process. This can help to reduce the need for specialized training and make it easier for operators to maintain the equipment.

Despite its many advantages, direct sale PU linear vibrating deck dewatering also has some drawbacks that should be considered. One potential downside is the initial cost of the equipment. While this method can be cost-effective in the long run, the upfront investment required to purchase and install the equipment can be significant.

Another potential drawback of direct sale PU linear vibrating deck dewatering is its maintenance requirements. Like any piece of equipment, vibrating decks require regular maintenance to ensure optimal performance. This can include cleaning, lubricating, and replacing parts as needed, which can add to the overall cost of operation.

Additionally, direct sale PU linear vibrating deck dewatering may not be suitable for all materials. Some materials may be too fine or too coarse to effectively dewater using this method, which can limit its applicability in certain industries. It is important to carefully consider the characteristics of the material being processed before choosing this dewatering method.

In conclusion, direct sale PU linear vibrating deck dewatering offers many benefits, including efficiency, versatility, and ease of operation. However, it is important to weigh these advantages against the potential drawbacks, such as cost and maintenance requirements. By carefully considering the specific needs of your industry and material, you can determine whether direct sale PU linear vibrating deck dewatering is the right choice for your dewatering needs.

How to Maximize Efficiency with Direct Sale PU Linear Vibrating Deck Dewatering

Direct sale PU linear vibrating deck dewatering is a crucial process in many industries, including mining, construction, and agriculture. This technology is used to separate solid particles from liquids, ensuring that the final product is of the highest quality. By maximizing efficiency with direct sale PU linear vibrating deck dewatering, businesses can increase productivity, reduce costs, and improve overall performance.

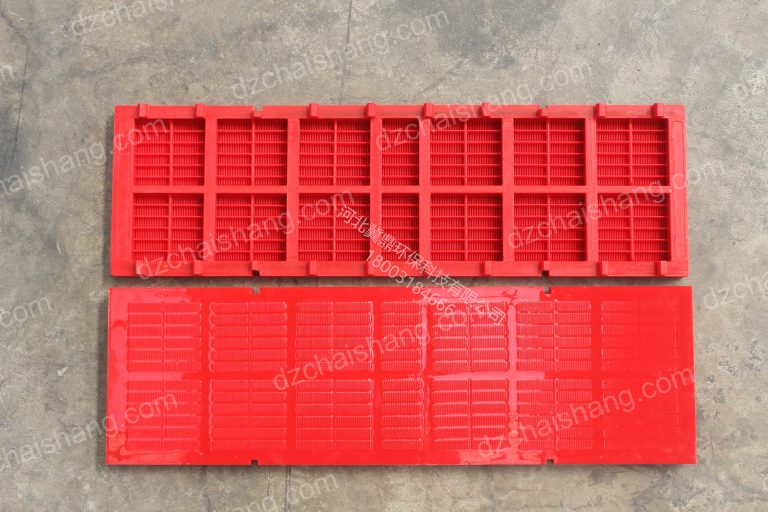

One of the key benefits of direct sale PU linear vibrating deck dewatering is its ability to handle large volumes of material quickly and effectively. This technology uses a series of vibrating screens to separate solids from liquids, allowing for efficient dewatering of slurry and other materials. By investing in direct sale PU linear vibrating deck dewatering equipment, businesses can process more material in less time, leading to increased productivity and higher output.

In addition to its speed and efficiency, direct sale PU linear vibrating deck dewatering also offers a high level of accuracy and precision. The vibrating screens used in this process are designed to separate particles of different sizes, ensuring that only the desired material is retained. This level of precision is essential for industries that require consistent and reliable results, such as mining and construction.

To maximize efficiency with direct sale PU linear vibrating deck dewatering, businesses should invest in high-quality equipment that is specifically designed for their needs. This includes choosing the right size and configuration of vibrating screens, as well as ensuring that the equipment is properly maintained and serviced. By selecting the right equipment and taking care of it properly, businesses can ensure that their dewatering process runs smoothly and efficiently.

Another important factor in maximizing efficiency with direct sale PU linear vibrating deck dewatering is proper training and education for employees. Operators should be trained on how to use the equipment effectively, as well as how to troubleshoot common issues that may arise. By investing in training and education for employees, businesses can ensure that their dewatering process is running at peak efficiency at all times.

In addition to equipment and training, businesses can also maximize efficiency with direct sale PU linear vibrating deck dewatering by implementing best practices and process improvements. This may include optimizing the dewatering process to reduce energy consumption, implementing automation and control systems to streamline operations, and regularly monitoring and analyzing performance data to identify areas for improvement.

By taking a comprehensive approach to maximizing efficiency with direct sale PU linear vibrating deck dewatering, businesses can achieve significant cost savings and performance improvements. This technology offers a range of benefits, including increased productivity, reduced costs, and improved product quality. By investing in high-quality equipment, providing proper training and education for employees, and implementing best practices and process improvements, businesses can ensure that their dewatering process is running at peak efficiency and delivering the best possible results.