The Benefits of Using a Conveyor Scraper for mining: How to Maximize Efficiency and Safety. Mining operations rely on conveyor systems to move materials from one place to another. To ensure that these systems run smoothly and efficiently, it is important to use the right type of scraper. In this blog post, we will discuss the benefits of using a conveyor scraper for mining, including how it can maximize efficiency and safety. We will also discuss the different types of scrapers available, such as polyurethane scraper blades, and how to choose the right one for your mining operation

Mining operations rely on conveyor systems to move materials from one place to another. To ensure that these systems run smoothly and efficiently, it is important to use the right type of scraper. A conveyor scraper is a device that is used to scrape material off the conveyor belt and into a collection bin. This helps to keep the conveyor belt clean and free of debris, which can cause blockages and other issues.

Using a conveyor scraper for mining can provide a number of benefits, including increased efficiency and safety. By removing debris from the conveyor belt, it can help to reduce the risk of blockages and other issues that can slow down production. This can help to maximize efficiency and reduce downtime. Additionally, it can help to reduce the risk of accidents, as debris can be a hazard for workers.

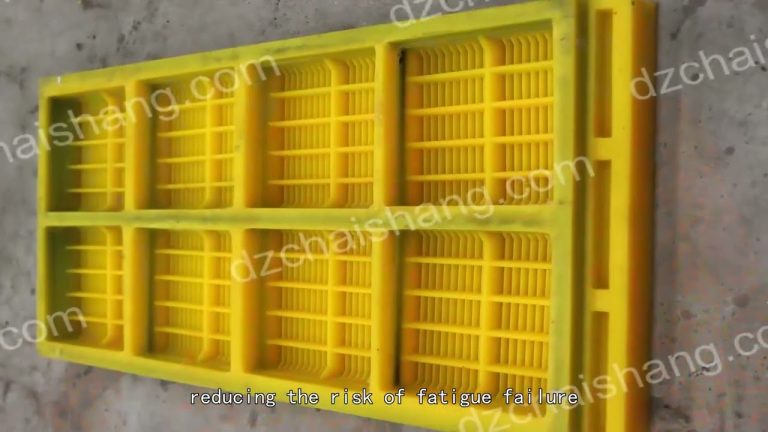

There are a number of different types of conveyor scrapers available, including polyurethane scraper blades. These blades are designed to be durable and long-lasting, and they can be used in a variety of mining operations. When choosing a scraper for your mining operation, it is important to consider the type of material you are working with, as well as the size and shape of the conveyor belt. This will help to ensure that you choose the right scraper for your needs.

Using a conveyor scraper for mining can help to maximize efficiency and safety. By removing debris from the conveyor belt, it can help to reduce the risk of blockages and other issues that can slow down production. Additionally, it can help to reduce the risk of accidents, as debris can be a hazard for workers. When choosing a scraper for your mining operation, it is important to consider the type of material you are working with, as well as the size and shape of the conveyor belt. This will help to ensure that you choose the right scraper for your needs.