تطور شاشات تعدين البولي يوريثين: تعزيز الكفاءة والمتانة في معالجة المعادن

مزايا شاشات البولي يوريثين المعيارية في تكنولوجيا الغربلة الحديثة: تحليل مقارن

في مجال تكنولوجيا الفحص الحديثة، أدى البحث عن حلول أكثر كفاءة ومتانة وفعالية من حيث التكلفة إلى تقدم كبير. ومن بين هذه الشاشات، برزت شاشات البولي يوريثين (PU) باعتبارها المرشح الأوفر حظًا، حيث تقدم عددًا كبيرًا من المزايا مقارنة بمواد الفحص التقليدية مثل الشبكات السلكية أو المطاط. يتعمق هذا التحليل المقارن في فوائد شاشات PU، خاصة في تطبيقات التعدين، ويوضح سبب تحولها بشكل متزايد إلى المادة المفضلة لمحترفي الصناعة.

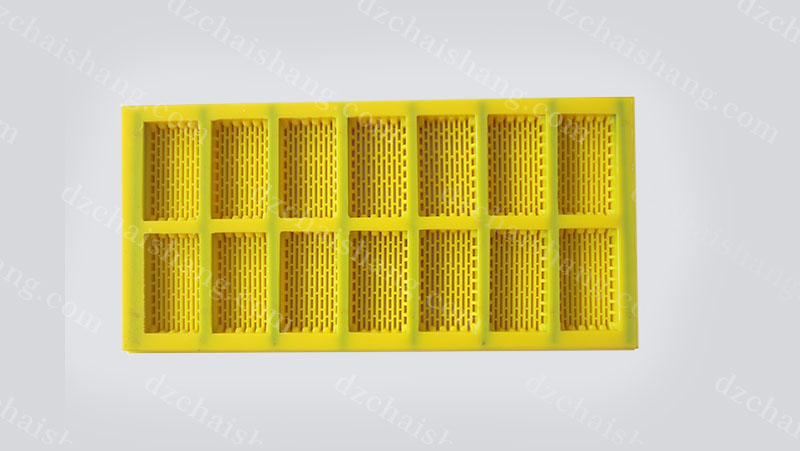

أحدثت شاشات وحدات البولي يوريثين، بخصائصها الفريدة، ثورة في عمليات الفحص. على عكس سابقاتها، تم تصميم هذه الشاشات لتحقيق أقصى قدر من الكفاءة والقدرة على التكيف. إحدى المزايا الأساسية لشاشات PU هي متانتها الاستثنائية. مادة البولي يوريثين هي مادة عالية المرونة يمكنها تحمل الظروف القاسية، بما في ذلك المواد الكاشطة والقوى عالية التأثير التي عادة ما تواجهها عمليات التعدين. تُترجم هذه المتانة إلى عمر أطول للشاشات، مما يقلل الحاجة إلى عمليات استبدال متكررة، وبالتالي خفض تكاليف التشغيل.

علاوة على ذلك، تسمح مرونة البولي يوريثين بتصميم شاشات معيارية يمكن تكييفها بسهولة مع متطلبات الفحص المختلفة. تعد هذه القدرة على التكيف أمرًا بالغ الأهمية في عمليات التعدين حيث يمكن أن تختلف طبيعة المادة التي يتم فحصها بشكل كبير. يمكن إعادة تشكيل أو استبدال شاشات PU المعيارية بسرعة وسهولة، مما يضمن أن تظل عملية الغربلة فعالة وفعالة، بغض النظر عن التغييرات في خصائص المواد. تعني هذه المرونة أيضًا أنه يمكن استخدام شاشات PU عبر مجموعة واسعة من التطبيقات، بدءًا من الغربلة الدقيقة إلى الخشنة، مما يجعلها حلاً متعدد الاستخدامات للعديد من الصناعات.

ميزة أخرى مهمة لشاشات PU المعيارية هي كفاءة الفحص المحسنة. يسمح تصميم هذه الشاشات، جنبًا إلى جنب مع خصائص البولي يوريثين، بفصل المواد بشكل أكثر فعالية. ويرجع ذلك جزئيًا إلى انخفاض احتمالية التعمية والربط، وهي مشكلات شائعة في مواد الفحص التقليدية التي يمكن أن تعيق الأداء بشكل كبير. يقلل السطح الأملس والمرونة التي تتميز بها شاشات PU من فرص تعلق الجزيئات في فتحات الشاشة، مما يضمن تدفقًا ثابتًا وفصلًا أفضل للمواد. لا تعمل هذه الكفاءة على تحسين جودة المنتج الذي تم فحصه فحسب، بل تعمل أيضًا على تحسين الإنتاجية الإجمالية لعملية الفحص.

أصبحت الاعتبارات البيئية أولوية متزايدة في العمليات الصناعية، وهنا أيضًا، توفر شاشات PU المعيارية فوائد. تقلل متانة البولي يوريثين وطول عمره من الحاجة إلى استبدال الشاشات بشكل متكرر، مما يؤدي إلى تقليل النفايات. بالإضافة إلى ذلك، يمكن أن تساهم كفاءة شاشات PU في تقليل استهلاك الطاقة في عمليات الفحص، حيث يمكن للآلات أن تعمل بشكل أكثر فعالية مع تقليل وقت التوقف عن العمل ومتطلبات الصيانة.

في الختام، فإن مزايا شاشات البولي يوريثين المعيارية في تكنولوجيا الغربلة الحديثة متعددة. إن متانتها وقدرتها على التكيف وكفاءتها تجعلها خيارًا مثاليًا للتعدين والتطبيقات الصناعية الأخرى. تؤكد الفوائد البيئية أيضًا على ملاءمتها للمشهد الصناعي الصديق للبيئة اليوم. مع استمرار تقدم التكنولوجيا، فمن المحتمل أن يصبح استخدام شاشات PU أكثر انتشارًا، مما يعزز مكانتها كعنصر حاسم في عمليات الفحص الفعالة والفعالة.

Advantages of polyurethane modular screens in Modern Screening Technology: A Comparative Analysis

In the realm of modern screening technology, the quest for more efficient, durable, and cost-effective solutions has led to significant advancements. Among these, polyurethane (PU) modular screens have emerged as a frontrunner, offering a plethora of advantages over traditional screening materials like wire mesh or rubber. This comparative analysis delves into the benefits of PU screens, particularly in mining applications, and elucidates why they are increasingly becoming the material of choice for industry professionals.

Polyurethane modular screens, with their unique properties, have revolutionized screening processes. Unlike their predecessors, these screens are designed for maximum efficiency and adaptability. One of the primary advantages of PU screens is their exceptional durability. Polyurethane is a highly resilient material that can withstand extreme conditions, including abrasive materials and high-impact forces commonly encountered in mining operations. This durability translates into a longer lifespan for the screens, reducing the need for frequent replacements and, consequently, lowering operational costs.

Moreover, the flexibility of polyurethane allows for the design of modular screens that can be easily adapted to various screening requirements. This adaptability is crucial in mining operations where the nature of the material being screened can vary significantly. pu modular screens can be quickly and easily reconfigured or replaced, ensuring that the screening process remains efficient and effective, regardless of the changes in material characteristics. This flexibility also means that PU screens can be used across a wide range of applications, from fine to coarse screening, making them a versatile solution for many industries.

Another significant advantage of PU modular screens is their improved screening efficiency. The design of these screens, combined with the properties of polyurethane, allows for a more effective separation of materials. This is partly due to the reduced likelihood of blinding and pegging, common issues with traditional screening materials that can significantly hinder performance. The smooth surface and flexibility of PU screens reduce the chances of particles getting stuck in the screen openings, ensuring a consistent flow and better separation of materials. This efficiency not only improves the quality of the screened product but also enhances the overall productivity of the screening operation.

Environmental considerations are increasingly becoming a priority in industrial operations, and here too, PU modular screens offer benefits. The durability and longevity of polyurethane reduce the need for frequent screen replacements, leading to less waste. Additionally, the efficiency of PU screens can contribute to lower energy consumption in screening operations, as machines can operate more effectively with less downtime and maintenance requirements.

In conclusion, the advantages of polyurethane modular screens in modern screening technology are manifold. Their durability, adaptability, and efficiency make them an ideal choice for mining and other industrial applications. The environmental benefits further underscore their suitability in today’s eco-conscious industrial landscape. As technology continues to advance, it is likely that the use of PU screens will become even more widespread, cementing their status as a critical component in efficient and effective screening operations.