Benefits of Using a Competitive Price Vibrator PU Coated Wire Sieve in Industrial Applications

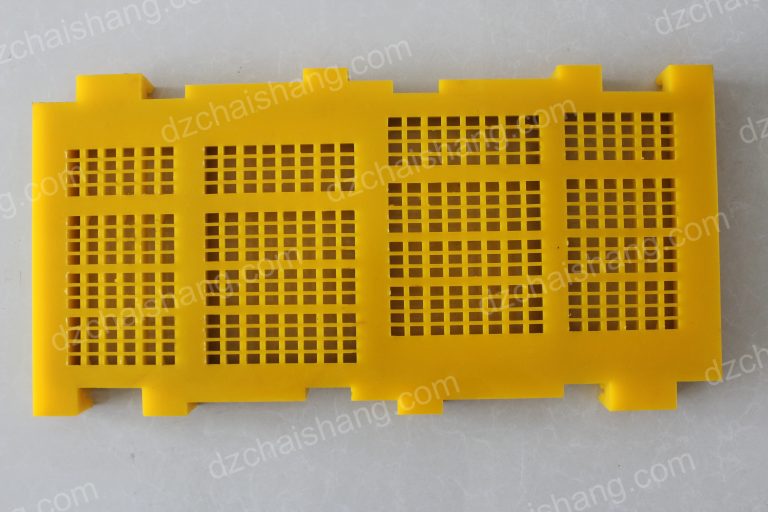

In industrial applications, having the right equipment is crucial for ensuring efficiency and productivity. One piece of equipment that is essential for many industries is a vibrator PU coated wire sieve. This type of sieve is designed to efficiently separate materials of different sizes, making it an invaluable tool for a wide range of applications.

One of the main benefits of using a competitive price vibrator PU coated wire sieve is its durability. The PU coating on the wire mesh provides a protective layer that helps prevent wear and tear, extending the lifespan of the sieve. This means that you can rely on this sieve to perform consistently over time, saving you money on frequent replacements.

In addition to its durability, a vibrator PU coated wire sieve is also highly efficient. The vibrating motion of the sieve helps to quickly and effectively separate materials, reducing processing time and increasing productivity. This is especially important in industries where time is of the essence, such as mining or construction.

Another advantage of using a competitive price vibrator PU coated wire sieve is its versatility. These sieves can be used for a wide range of materials, from fine powders to larger particles. This versatility makes them a valuable tool for industries that work with a variety of materials, allowing for greater flexibility in processing.

Furthermore, a vibrator PU coated wire sieve is easy to clean and maintain. The smooth surface of the PU coating makes it simple to wipe down and remove any build-up of materials, ensuring that the sieve remains in optimal condition. This ease of maintenance helps to prolong the life of the sieve and ensures that it continues to perform at its best.

Additionally, a competitive price vibrator PU coated wire sieve is cost-effective. Despite its high-quality construction and efficiency, these sieves are available at a competitive price point, making them a smart investment for businesses looking to improve their processing capabilities without breaking the bank. This affordability makes them accessible to a wide range of industries, from small businesses to large corporations.

In conclusion, the benefits of using a competitive price vibrator PU coated wire sieve in industrial applications are clear. From its durability and efficiency to its versatility and ease of maintenance, this type of sieve offers a range of advantages that can help businesses improve their processing capabilities and increase productivity. With its cost-effective price point, a vibrator PU coated wire sieve is a smart investment for any industry looking to streamline their operations and achieve better results.

How to Choose the Right Competitive Price Vibrator PU Coated Wire Sieve for Your Specific Needs

When it comes to choosing the right competitive price vibrator PU coated wire sieve for your specific needs, there are several factors to consider. From the size and shape of the sieve to the material it is made from, each aspect plays a crucial role in determining the effectiveness and efficiency of the sieve in your operations.

One of the first things to consider when selecting a vibrator PU coated wire sieve is the size of the sieve itself. The size of the sieve will determine the amount of material that can be processed at one time, as well as the efficiency of the sieving process. Larger sieves are ideal for processing larger quantities of material, while smaller sieves are better suited for more precise and detailed sieving tasks.

In addition to size, the shape of the sieve is also an important factor to consider. The shape of the sieve will determine how the material flows through the sieve, as well as how evenly it is distributed across the surface of the sieve. Some common shapes for vibrator PU coated wire sieves include round, square, and rectangular, each with its own advantages and disadvantages depending on the specific needs of your operation.

Another important consideration when choosing a vibrator PU coated wire sieve is the material it is made from. PU coated wire sieves are known for their durability and longevity, making them an ideal choice for heavy-duty industrial applications. The PU coating helps to protect the wire mesh from corrosion and wear, ensuring that the sieve will last for years to come.

When selecting a vibrator PU coated wire sieve, it is also important to consider the type of vibration mechanism used. Some sieves use a rotary vibration mechanism, while others use a linear vibration mechanism. The type of vibration mechanism will determine how the material is agitated and distributed across the surface of the sieve, affecting the efficiency and effectiveness of the sieving process.

In addition to size, shape, material, and vibration mechanism, it is also important to consider the overall quality and reputation of the manufacturer when selecting a vibrator PU coated wire sieve. Look for manufacturers with a proven track record of producing high-quality sieves that are built to last. Reading customer reviews and testimonials can also help you gauge the reliability and performance of a particular sieve before making a purchase.

In conclusion, choosing the right competitive price vibrator PU coated wire sieve for your specific needs requires careful consideration of several factors, including size, shape, material, vibration mechanism, and manufacturer reputation. By taking the time to research and compare different options, you can ensure that you select a sieve that will meet your needs and provide reliable performance for years to come.