Exploring the Benefits of Using Chinese Vibrators in the Construction Industry

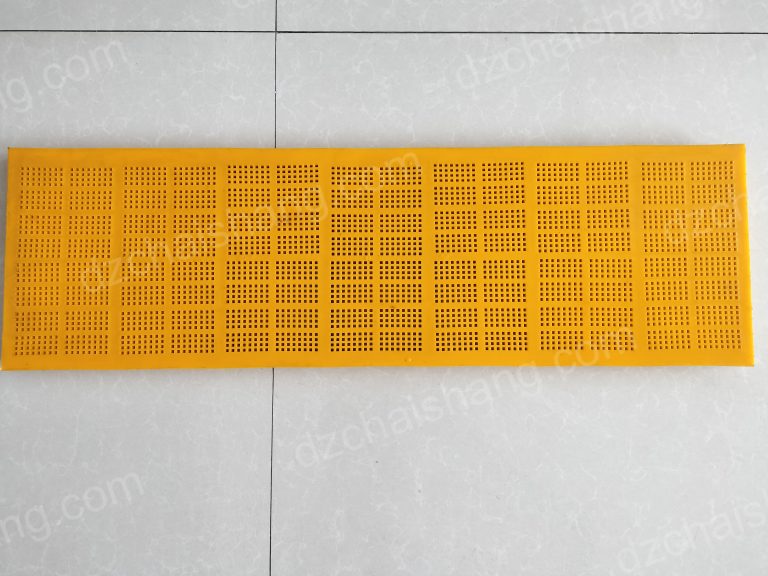

In the construction industry, efficiency and precision are key factors in completing projects on time and within budget. One tool that has become increasingly popular for achieving these goals is the Chinese vibrator. These vibrators are used to consolidate concrete and remove air bubbles, ensuring a smooth and durable finish. One of the main advantages of using Chinese vibrators is their ability to work with fine polyurethane Panels, which are essential for achieving a high-quality finish in construction projects.

Chinese vibrators are designed to work with a variety of materials, including polyurethane panels. These panels are lightweight and flexible, making them ideal for use in construction projects where a smooth finish is desired. When used in conjunction with Chinese vibrators, polyurethane panels can help to evenly distribute the vibration throughout the concrete, ensuring that it is properly consolidated and free of air bubbles.

One of the key benefits of using Chinese vibrators with polyurethane panels is their ability to achieve a high level of compaction in a short amount of time. This is essential for ensuring that the concrete is properly consolidated and free of voids, which can weaken the structure over time. By using Chinese vibrators with polyurethane panels, construction workers can achieve a smooth and durable finish in a fraction of the time it would take using traditional methods.

Another advantage of using Chinese vibrators with polyurethane panels is their ability to work in tight spaces. In construction projects where access is limited, Chinese vibrators can be used to consolidate concrete in areas that would be difficult or impossible to reach with traditional tools. This can help to speed up the construction process and reduce the overall cost of the project.

In addition to their efficiency and versatility, Chinese vibrators are also known for their durability and reliability. These vibrators are built to withstand the rigors of the construction site, making them a valuable investment for any construction company. By using Chinese vibrators with polyurethane panels, construction workers can achieve a high level of compaction without sacrificing quality or durability.

Overall, Chinese vibrators are a valuable tool for construction projects that require a high level of compaction and precision. By using these vibrators with polyurethane panels, construction workers can achieve a smooth and durable finish in a fraction of the time it would take using traditional methods. With their efficiency, versatility, and durability, Chinese vibrators are an essential tool for any construction project that requires a high level of precision and quality.

The Advantages of Polyurethane Panels in Aggregate Processing Operations

Polyurethane panels have become increasingly popular in aggregate processing operations due to their numerous advantages over traditional materials. One of the key benefits of using polyurethane panels in this industry is their durability. These panels are made from a tough, wear-resistant material that can withstand the harsh conditions of aggregate processing, including high impact and abrasion.

In addition to their durability, polyurethane panels are also highly flexible, making them ideal for use in vibrating screens and other equipment commonly used in aggregate processing operations. The flexibility of these panels allows them to absorb the energy generated by the vibrating equipment, reducing stress on the machinery and extending its lifespan.

Another advantage of polyurethane panels is their resistance to corrosion and chemical damage. Unlike metal or rubber panels, polyurethane panels are not affected by moisture, chemicals, or other corrosive substances commonly found in aggregate processing operations. This resistance to corrosion ensures that the panels maintain their integrity and performance over time, even in the harshest environments.

Polyurethane panels are also lightweight, making them easy to handle and install. This can result in significant cost savings for aggregate processing operations, as less manpower and equipment are required to transport and install the panels. Additionally, the lightweight nature of polyurethane panels reduces the overall weight of vibrating equipment, which can lead to improved energy efficiency and reduced maintenance costs.

Furthermore, polyurethane panels are available in a wide range of sizes and configurations, making them suitable for a variety of applications in aggregate processing operations. Whether used in vibrating screens, dewatering screens, or other equipment, polyurethane panels can be customized to meet the specific needs of each operation. This versatility allows operators to optimize their equipment for maximum efficiency and productivity.

In addition to their practical benefits, polyurethane panels also offer aesthetic advantages. These panels are available in a variety of colors and finishes, allowing operators to customize the appearance of their equipment to match their branding or aesthetic preferences. This can help create a more professional and cohesive look for aggregate processing operations, enhancing the overall image of the facility.

Overall, the advantages of using polyurethane panels in aggregate processing operations are clear. From their durability and flexibility to their resistance to corrosion and ease of installation, polyurethane panels offer a range of benefits that can improve the efficiency, performance, and appearance of vibrating equipment in this industry. By choosing polyurethane panels for their operations, aggregate processors can enjoy a cost-effective and reliable solution that will help them achieve their production goals.