Exploring the Uses and Benefits of polyurethane screen mesh and Belts in Various Industries

Polyurethane, a versatile and durable material, has found extensive applications in various industries, particularly in the manufacturing of screen mesh and belts. The unique properties of polyurethane, such as its high resistance to wear and tear, flexibility, and ability to withstand extreme temperatures, make it an ideal choice for these applications.

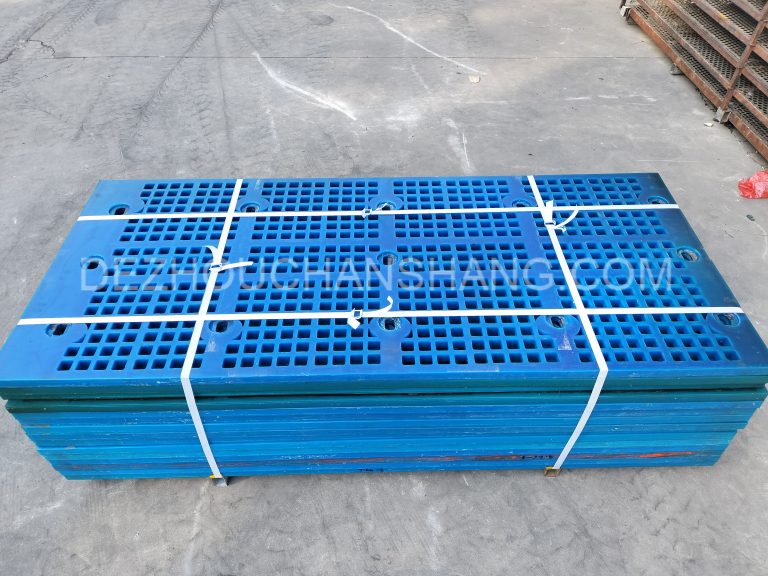

Polyurethane screen mesh, also known as pu Vibrating Mesh, is widely used in the mining industry. The mining process involves the separation of valuable minerals from waste rock, a process that requires a durable and efficient screening system. Polyurethane screen mesh, with its high tensile strength and elasticity, provides an effective solution for this purpose. It is capable of screening large volumes of materials, reducing the chances of blockages, and ensuring a smooth flow of materials. Moreover, its resistance to corrosion and abrasion makes it suitable for use in harsh mining conditions, thereby increasing its lifespan and reducing maintenance costs.

In addition to mining, polyurethane screen mesh is also used in the construction industry. It is used in the screening of construction materials such as sand, gravel, and crushed stone. The flexibility of polyurethane allows the screen mesh to vibrate without breaking, thereby increasing its efficiency in separating different sizes of materials. Furthermore, its resistance to weather conditions and UV radiation makes it suitable for outdoor use.

On the other hand, polyurethane belts have found their niche in the manufacturing and packaging industries. These belts are used in conveyor systems to transport goods from one point to another. The high tensile strength of polyurethane ensures that the belts can carry heavy loads without breaking. Its flexibility allows the belts to bend around pulleys without cracking, thereby ensuring a smooth and continuous flow of goods. Moreover, polyurethane belts are resistant to oils, fats, and chemicals, making them suitable for use in food processing and chemical industries.

The use of polyurethane belts is not limited to conveyor systems. They are also used in power transmission systems in various machines. The high efficiency of polyurethane belts in transmitting power, coupled with their durability, makes them an ideal choice for this purpose. They are capable of operating at high speeds without generating excessive heat, thereby reducing energy consumption and increasing the efficiency of machines.

In conclusion, the use of polyurethane in the manufacturing of screen mesh and belts has revolutionized various industries. Its unique properties such as high tensile strength, flexibility, and resistance to wear and tear, corrosion, and extreme temperatures have made it an ideal material for these applications. The use of polyurethane screen mesh in the mining and construction industries has increased the efficiency of screening processes, while the use of polyurethane belts in the manufacturing and packaging industries has improved the efficiency of conveyor and power transmission systems. Therefore, polyurethane continues to be a material of choice in various industries, thanks to its versatility and durability.